Technology proposal

Summary

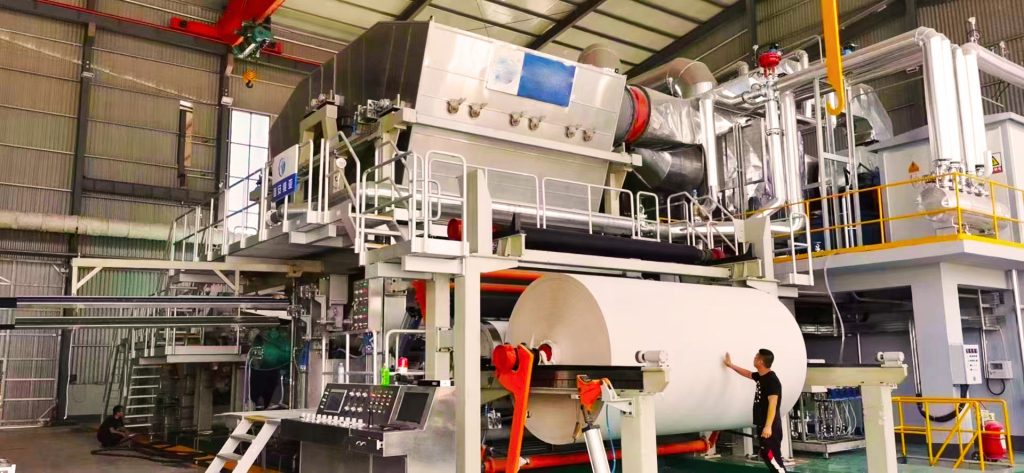

The scope of supply for the main equipment of the paper machine is one 2200/300 fourdrinier multi-cylinder paper machine, including a hydraulic pope-reel and a reel stand.

Paper machine process (see 2200/300 fourdrinier paper machine scheme diagram for details)

The wire section adopts two layer fourdrinier - two nips jumbo press - Drying section consists of 30 sets of φ1800 drying cylinder. The arrangement of the drying cylinders is 6+6+8+sizing machine+2+8+ calender+QCS + pope-reel +rewinder.

This machine is arranged in one floor, the left-hand arrangement (from the pope-reel to the headbox, the drive part is on the left side).

The standards referenced by this machine (all unlisted parts are in accordance with national or industry standards)

1.General technology conditions for light industrial machinery QB/T14253

2.General technology conditions for weldments of light industrial machinery QB/T1588.1

3.General technology requirements for light industrial machinery cutting parts QB/T1588.2

4.General technology requirements for assembly of light industrial machinery QB/T1588.3

5.General technology conditions for light industrial machinery painting QB/T1588.4

6.General technology requirements for packaging of light industrial machinery QB/T1588.5

7.Fourdrinier multi cylinder board machine 7QB/T1627

8.Technical specifications for cast iron drying cylinders used in papermaking machinery ZBY91003

9.Dynamic balance of paper making machinery rollers and drying cylinders GB 5799

10.Technical Specification for Construction and Acceptance of Pulp and Paper Professional Equipment Installation Engineering

11.Technical specifications for vacuum rollers, general components of papermaking machinery QB/T 1422.2

12.General components of papermaking machinery - Technical requirements for ordinary cast iron rollers QB/T 1422.3